Silicat – silicate facade plaster

According to EN 15824:2009

Silicate facade plaster

Component of thermal insulation system certified according ETAG 004, ETA 13/0214

Category: Facade finishing coats and paints

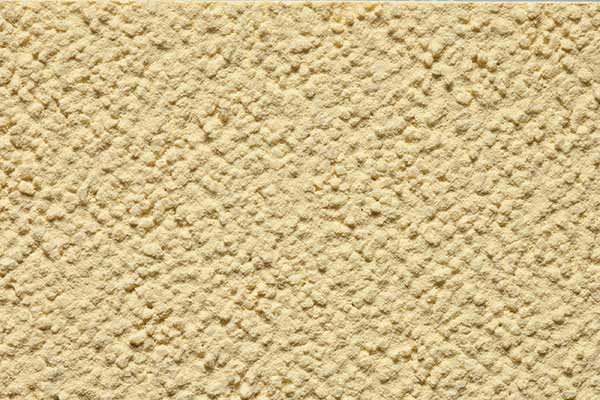

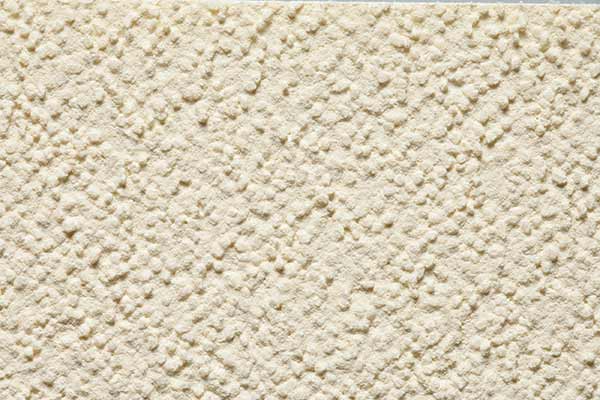

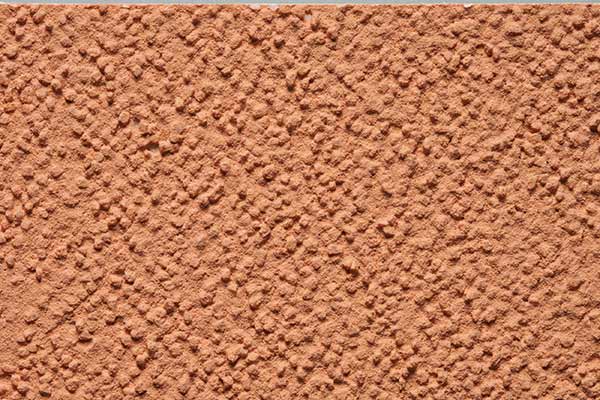

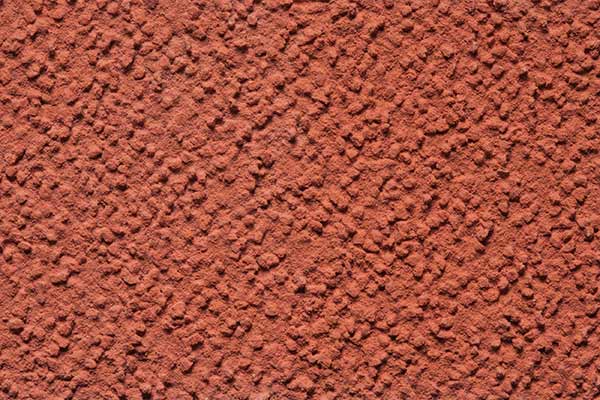

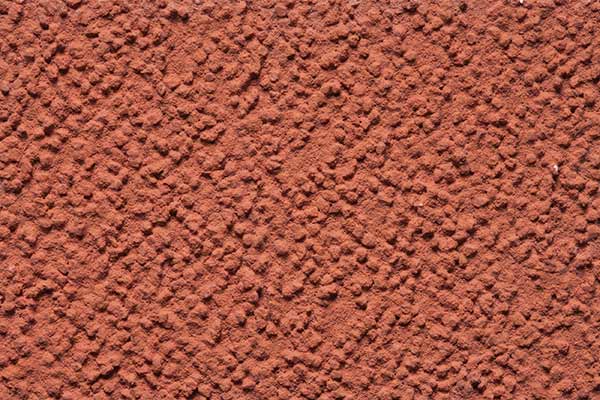

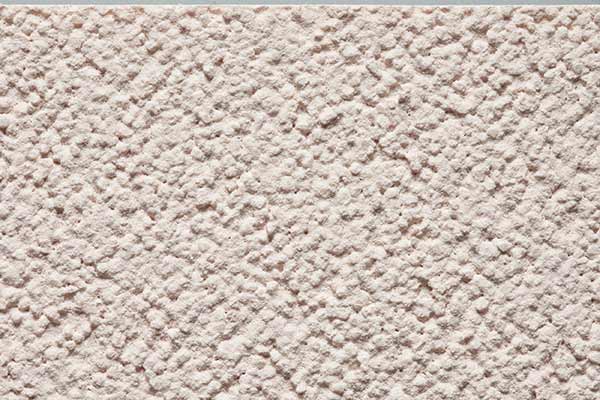

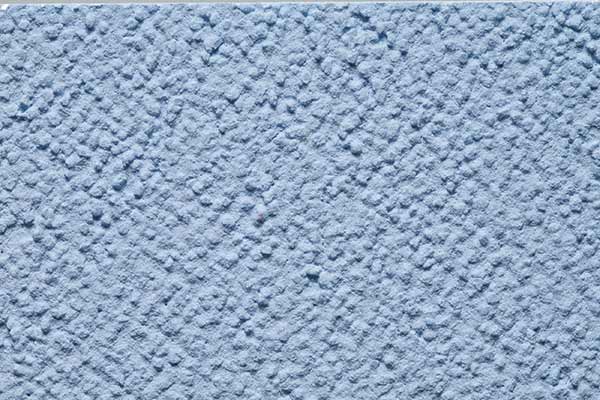

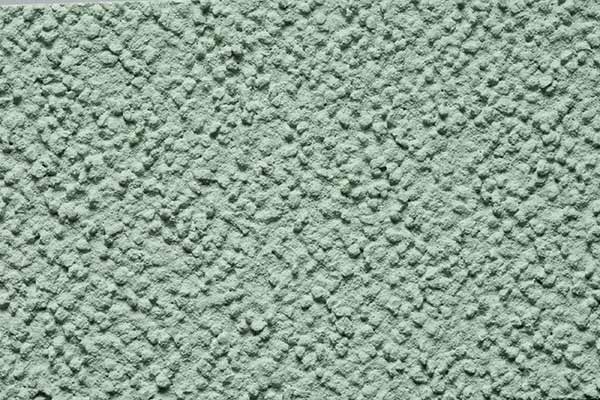

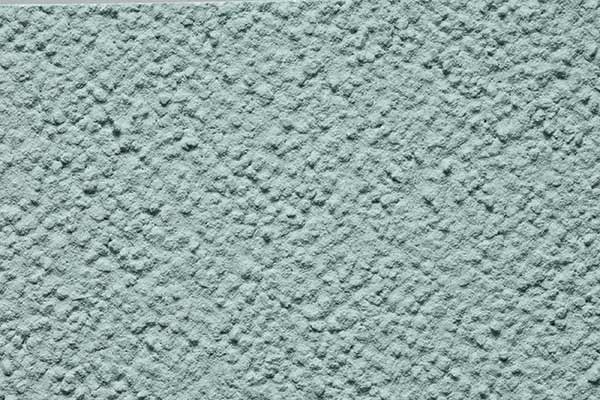

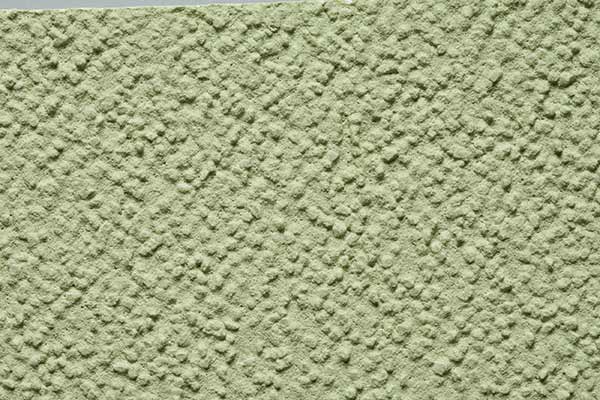

Color Gallery

Deviations from the actual colors are possible. It is recommended to choose the color based on the actual catalogs of plasters and paints, which you can find at our distributors.

-751A

-751B

-751C

-751D

-751E

-751F

-752A

-752B

-752C

-752D

-752E

-752F

-753A

-753B

-753C

-753D

-753E

-753F

-754A

-754B

-754C

-754D

-754E

-754F

-755A

-755B

-755C

-755D

-755E

-755F

-756A

-756B

-756C

-756D

-756E

-756F

-757A

-757B

-757C

-757D

-757E

-757F

-758A

-758B

-758C

-758D

-758E

-758F

-759A

-759B

-759C

-759D

-759E

-759F

-760A

-760B

-760C

-760D

-760E

-760F

-761A

-761B

-761C

-761D

-761E

-761F

-762A

-762B

-762C

-762D

-762E

-762F

-763A

-763B

-763C

-763D

-763E

-763F

-764A

-764B

-764C

-764D

-764E

-764F

-765A

-765B

-765C

-765D

-765E

-765F

-766A

-766B

-766C

-766D

-766E

-766F

-767A

-767B

-767C

-767D

-767E

-767F

-768A

-768B

-768C

-776E

-776F

-777A

-777B

-777C

-777D

-777E

-777F

-778A

-778C

-778D

-778E

-778F

-779A

-779B

-779C

-779D

-779E

-779F

-780A

-780B

-780C

-780D

-780E

-780F

-781A

-781B

-781C

-781D

-781E

-781F

-782A

-782B

-782C

-782D

-782E

-782F

-783A

-783B

-783C

-783D

-783E

-783F

-784A

-784B

-784C

-784D

-784E

-784F

-785A

-785B

-785C

-785D

-785E

-785F

Description:

PURPOSE

SILICAT is a ready for work plaster in paste form, based on acrylate dispersion and potassium water glass, with added mineral grains, colorants and preservatives. The product is designed for application of fine decorative protective covering on facade, as on interior walls and elements. The silicate plaster creates colorful water-repellent surface, with high vapor permeability and durability to polluted urban air and heavy weather conditions, preventing the formation of molds, polyps and fungi, on the facades. SILICAT is highly recommended material, when it is necessary to apply the finishing coat at high summer temperatures, due to its ability to get dry from inside to outside and giving more time for structuring. The product gives possibilities for rich variety of architectural solutions for facades and individual facade elements, with a wide color range and different sizes of the structural grains.

The color scale is created with high-quality, long-lasting pigments, providing choices of 210 colors. The final decorative effect could be with dragged or scratched structure.

Declaration of Performance (DoP)

Silicat – silicate facade plaster

Declaration of Performance (DoP)

DECLARATION OF PERFORMANCE

According with Regulation (EU) №305/2011

SILICAT

№ 20130709-07-D

1. Unique Identification Code of Product Type:

SILICAT

2. Type, Batch, or Serial Number:

Silicate facade plaster (batch number printed on the package)

3. Intended Use or Uses:

Silicate-based mixture for protective and decorative finishing coats on facades and exterior walls.

4. Manufacturer Information:

TERAZID Ltd.

5 „5004” Str., Gara Iskar, Sofia 1528, Bulgaria

Tel.: +359 2 979 9971

E-mail: office@terazid.com

5. Authorised Representative:

Not applicable.

6. Assessment and Verification System:

System 2+

7. European Technical Assessment:

ETAG 004 — The notified body 1020 – Technical and Test Institute For Construction Prague has issued European Technical Assessment ETA-13/0214 according to ETAG 004.

The notified body has:

-

Performed the initial inspection of the factory and the factory production control

-

Conducted continuous surveillance, assessment, and approval of the factory production control

Certificate Issued:

EC Certificate of Factory Production Control №1020-CPD-060037435

This certificate attests that all provisions concerning the attestation of factory production control described in ETA-13/0214 have been applied.

8. Declared Performance:

| TERAZID Ltd. 5 “5004” Str. Gara Iskar, Sofia, Bulgaria |

||

|---|---|---|

| Essential characteristics | Performance | Harmonized technical specification |

| Reaction to fire | A2 – s1, d0 | BDS EN 13501-1:2007+A1:2009 |

| Density | 1950 kg/m³ | BDS EN 1015-6 |

| Adhesion with the base | 1.0 MPa | BDS EN 24624 |

| Coefficient of water vapour transmission | 28 g/m²·d V2 |

BDS EN 15824 |

| Coefficient of capillary absorption of water – c | 0.25 kg/m²·h0.5 class W2 |

BDS EN 15824 |

| pH at 20°C | 8.2 | BDS EN ISO 787-9 |

| Content of volatile organic compounds /VOC/ | < 40 g/l | BDS EN ISO 11890-2 |

9. Conformity:

The performance of the product identified in points 1 and 2 is in conformity with the declared performance in point 8.

This declaration of performance is issued under the sole responsibility of the manufacturer identified in point 4.

Technical Data Sheet (TDS)

Silicat – silicate facade plaster

Technical Data Sheet (TDS)

TECHNICAL DATA SHEET

SILICAT

Silicate Facade Plaster

Silicate-based mixture for protective and decorative finishing coats on facades and exterior walls

In accordance with the requirements of ETAG 004

PURPOSE

SILICAT is a ready-to-use finishing coat based on potassium waterglass and polymers, with added mineral fillers, pigments, and preservatives.

It is used for creating fine protective and decorative coatings on facades and exterior walls, forming a white or colourful waterproof rough surface.

The product offers a wide variety of architectural solutions for facades and individual facade elements.

It is particularly recommended for work at high summer temperatures, as its composition delays film formation, extending the structuring time.

SILICAT features:

-

Wide range of colours and structural grain sizes

-

High-quality, weather-resistant pigments

-

Decorative options: “dragged” or “scratched” structure

-

Colouring available according to a catalogue of 210 colours

SILICAT is a component of the External Thermal Insulation Composite System TERAZID BIO CLIMA, approved with ETA – 13/0214.

PROPERTIES

-

Ready-to-use

-

Vapour-permeable

-

Water-repellent

-

Resistant to various weather conditions

-

UV-resistant

PREPARATION OF THE BASE

The base must be:

-

Dry, strong, and free of grease, dust, and cracks

-

Smooth and free of holes

-

Repaired where necessary to ensure evenness and strength

Unstable areas, old paints, and grease spots must be removed.

The surface must be primed with TERAZID G-33 at least 24 hours before applying SILICAT.

CHARACTERISTICS AND TECHNICAL DATA

-

Colour: According to catalogue

-

Type: Homogeneous granular mass

-

Density: 1950 kg/m³

-

Resistance to vapour passing: µ = 410

-

Minimal temperature of film formation: +8°C

-

Resistance to rain: After 24 hours (at 20°C, 50% humidity)

-

Bond strength with concrete after 7 days: 1.65 MPa

Structures:

-

Dragged:

-

Fine-grained: 1.5 mm

-

Middle-grained: 2.0 mm

-

Grained: 2.5 mm

-

Large-grained: 3.0 mm

-

-

Scratched:

-

Micro-grained: 1.0 mm

-

Fine-grained: 1.5 mm

-

Middle-grained: 2.0 mm

-

APPLICATION AND PROCESSING

-

Apply SILICAT at least 24 hours after priming with TERAZID G-33.

-

Mix the content of 2–3 buckets in a larger container for uniformity.

-

If needed, dilute slightly with TERAZID G-33 — do not add any other ingredients.

-

Stir the content with a mechanical mixer before application.

-

Do not use rusty tools.

Application details:

-

The thickness of the coating is determined by the marble grain size.

-

Apply manually with a plastic mortarboard.

For “Dragged” Structure:

-

Apply, wait 10 minutes, then smooth to achieve the desired effect.

-

Can be structured vertically, horizontally, diagonally, or with circular movements.

For “Scratched” Structure:

-

Structure with circular movements without pressure.

Important:

-

Work continuously across surfaces to avoid visible joints.

-

Use paper tape to protect adjacent surfaces in different colours.

-

Avoid direct sunlight, rain, and strong wind during application.

CONSUMPTION

-

Dragged structure:

-

1.5 mm: 2.5 kg/m²

-

2.0 mm: 2.9 kg/m²

-

2.5 mm: 3.6 kg/m²

-

3.0 mm: 4.3 kg/m²

-

-

Scratched structure:

-

1.0 mm: 1.9 kg/m²

-

1.5 mm: 2.8 kg/m²

-

2.0 mm: 3.5 kg/m²

-

TOOLS FOR WORK

-

Mechanical mixer

-

Stainless steel trowel

-

Plastic mortarboard

-

Brush

WEATHER CONDITIONS FOR APPLICATION

-

Minimum 24-hour temperature of the base: +5°C

-

Maximum temperature: +40°C

-

Do not apply during rain, forecasted rain, direct sunlight, or strong winds.

FORM OF DELIVERY

-

Paste in a plastic bucket of 25 kg.

NOTES

-

Technical data are defined at 20°C and 50% relative humidity.

Under different weather conditions, process times may vary. -

Product information is based on the manufacturer’s practical experience and specialized laboratory tests.

-

Do not mix with other building materials.

-

Hazard and precautionary statements about SILICAT can be found in its Safety Data Sheet.

STORAGE

-

Shelf life: 12 months in the originally sealed package

-

Storage conditions: Store in a dry place, protected from freezing.

| CE | ||

| TERAZID Ltd. | ||

| 5 “5004” Str. Gara Iskar, Sofia, Bulgaria | ||

| ETAG 004 | ||

| NB 1020 | ||

| DoP № 20130709-07-D | ||

| SILICAT | ||

| Silicate-based mixture for protective and decorative finishing coats on facades and exterior walls |

||

| Reaction to fire | A2 – s1, d0 | |

| Density | 1950 kg/m³ | |

| Adhesion with the base | 1.0 MPa | |

| Coefficient of water vapour transmission | 28 g/m²·d V2 |

|

| Coefficient of capillary absorption of water – c | 0.25 kg/m²·h0.5 class W2 |

|

| pH at 20°C | 8.2 | |

| Content of volatile organic compounds /VOC/ | < 40 g/l | |

The manufacturer recommends checking the suitability of the product in the Technical Data Sheet. The same is responsible for the product quality, but not for the ways and conditions of its applying. The information into the present Technical Data Sheet is reliable but only if the product is used under stated conditions. The responsibility of any other usage of the product, including its usage in a combination with any other product or a process, is borne by the user.

Material Safety Data Sheet (MSDS)

Silicat – silicate facade plaster

Material Safety Data Sheet (MSDS)

MATERIAL SAFETY DATA SHEET

According to (EU) 830/2015

SILICAT

1. Identification of the Substance/Mixture and of the Company

1.1. Product identifier – SILICAT 1.2. Application of the substance Silicate facade plaster. 1.3. Details of the supplier of the safety data sheet TERAZID Ltd. 5, 5004 Street, Gara Iskar 1528 Sofia, Bulgaria tel. +3592/9799971, office@terazid.com 1.4. Emergency telephone number 112 UMHATEM “Pirogov” (toxicology) – +3592/9154409; +3592/9154233

2. Hazards Identification

2.1. Classification of the substance or mixture – Classification in accordance with the Regulation (ЕО) 1272/2008 – CLP The product is NOT classified as „dangerous“. 2.2. Label elements Precautionary statements: P101 – If medical advice is needed, have product container or label at hand. P102 – Keep out of reach of children. P262 – Do not get in eyes, on skin, or on clothing. P305 + P351 + P313 – IF IN EYES: Rinse cautiously with water for several minutes. Get medical advice/attention. P280 – Wear protective gloves/protective clothing/eye protection/face protection. P301 + P311 – IF SWALLOWED: Call a POISON CENTER or doctor/physician. P410 – Protect from sunlight. P401 – Store at temperatures higher than +5°C. 2.3. Other hazards None. For all warnings and recommendations, see Section 15.

3. Composition/information on ingredients

General chemical description – Acrylic-silicate dispersion, containing potassium waterglass, mineral fillers and modified additives. Information of the substances in accordance with CLP 1272/2008/EC Does not contain products, presenting in this section.

4. First Aid Measures

4.1. Description of the first aid measures Inhalation – Remove the person to fresh air. If the symptoms continue, immediately seek for qualified medical help. Skin contact – Immediately rinse the area of the contact with plenty of water, then wash it thoroughly with soap and water. Eye contact – Rinse with plenty of water for a period of at least 15 minutes and open eyelid. Seek for qualified medical help. Ingestion – Wash the mouth and the throat. Drink plenty of water. Seek for qualified medical help. 4.2. Most important symptoms and effects, both acute and delayed None. 4.3. Indication of any immediate medical attention and special treatment needed – see p. 4.1.

5. Firefighting Measures

SILICAT is non-combustible and prevents flames from spreading. Does not support combustion of other products. 5.1. Extinguishing media Water mist, water spray – sprayer, dry chemical, foam, carbon dioxide. Inappropriate extinguishing media – water under pressure. 5.2. Special hazards, arising from the substance or mixture – Non known 5.3. Advice for firefighters – Standard protective equipment when extinguishing a fire.

6. Accidental Release Measures

6.1. Personal precautions, protective equipment and emergency procedures Gloves, masks, protective clothing for work. Contact with skin and eyes should be avoided. 6.2. Environmental precautions Prevent this product from release in the environment. Measures should be taken for preventing contamination of surface and underground watercourses, soil, as well as falling into the drains. In the event of an accident and/or spill of the product, measures for localization and limitation should be taken, and the collected amount of the product should be temporarily stored into a special, tightly closed and labeled containers, and after that they should be transferred to people, holding permits under the Article 37 of the Waste Management Act (publication SG, issue 53, 2012). 6.3. Methods and materials for containment and cleaning up The spilled amount should be mechanically removed, and then the place should be washed thoroughly with water in accordance with the measures under art.6.2. Collected amount should be stored in special, tightly closed and labeled containers and to be temporarily stored on the territory of the company, and after that they should be transferred to people, holding a permit under the Waste Management Act (WMA).

7. Handling and Storage

7.1. Precautions for safe handling The product should be used only according to its main purpose. Avoid skin and eye contact. Keep the package tightly closed after usage. 7.2. Conditions for safe storage, including any incompatibilities It should be stored in ventilated and dry places, into the originally sealed containers. Temperatures lower than +5C and higher than +40C should be avoided. It should be separately stored from food and drinks. 7.3. Specific Usage There is no specific usage. It should be used only according to its main purpose.

8. Exposure Controls/Personal Protection

8.1. Control parameters – No special protection measures are necessary. 8.2. Exposure controls 8.2.1. Respiratory protection – prolonged inhalation of fumes should be avoided. 8.2.2. Skin protection – skin contact should be avoided, wear protective gloves. Clothing, soaked with the product should be changed. 8.2.3. Eye protection – eye contact should be avoided, wear safety glasses. 8.2.4. Common protection – it should be stored away from food, drinks and food for animals.

9. Physical and Chemical Properties

9.1. Information on basic physical and chemical properties

-

Appearance: Liquid paste material

-

Odour: Light

-

pH at 20°C: 8.2

-

Density: 1950 kg/m³

-

Solubility: Partial

-

Explosive properties: Non-explosive

9.2. Other information – no data.

10. Stability and reactivity

10.1. Reactivity – no hazardous reactions. 10.2. Chemical stability – the product is stable under storage and usage in accordance with the indications. 10.3. Possibility of hazardous reactions – in accordance with section 10.1. 10.4. Conditions to avoid – temperatures lower than +5C and higher than 40C should be avoided. 10.5. Incompatible materials – no data. 10.6. Hazardous decomposition products – it is unlikely to release carbon oxides at fire.

11. Toxicological information

11.1. Information for the toxicological effects Toxicological properties of the product are not tested. The product is classified under the conventional method in accordance with Regulation (ЕО) 1272/2008 – CLP. On the basis of its composition, the product can be defined as not having any toxic effects under a proper usage. Ingestion – The product is not hazardous of acute poisoning. Inhalation – It is not considered as harmful at normal conditions. Skin contact – Prolonged contact may cause irritation. Eye contact – Prolonged and repeated contact may cause irritation and redness.

12. Ecological information

12.1. Toxicity Polymer dispersion data: Toxicity to fish: LC50 (96 h) > 100 mg/l, (OECD Directive 203, static) Aquatic invertebrates: ЕC50 (48 h) > 100 mg/l, (OECD Directive 202, part 1, static) Aquatic plants: ЕC50 (72 h) > 100 mg/l, (OECD Directive 201) Micro-organisms/Effect of the active sediment: ЕC20 (0,5 h) > 100 mg/l, active sediment (DIN EN ISO 8192-OECD 209-88/302/EEC, P. C) On the basis of the experience, the product is not expected to be hazardous to the environment. 12.2. Persistence and degradability – No data. 12.3. Bio-accumulative potential – Accumulation in the organism is not expected. 12.4. Mobility in soil This product is not biologically mobile. 12.5. Results of PBT and vPvB assessment – the product meets the criteria of PBT (persistent, bio-accumulative and toxic) and vPvB (very persistent and very bio-accumulative). 12.6. Other adverse effects No data. General information: Do not allow the product to enter into the soil or natural watercourses.

13. Disposal considerations

Product waste, such as residual quantities and packages, should be collected into a special, tightly sealed and labelled containers, temporarily stored, and after that to be transferred to people, holding a permit in accordance with article 37 of the Waste Management Act (publication SG, issue 53, 2012). Waste code, in accordance with Regulation №2 from 23.07.2014 for Waste Classification: 08 01 20 – liquid suspensions of paints, others than those mentioned in 08 01 19 Waste Packages code: 15 01 02 – plastic packages. Completely empty the packages and dispose them in accordance with the local regulations.

14. Transport information

It is not a hazardous load, in accordance with RID, ADR, ADNR, IMDG, IATA-DGR. It should be transported under the respective rules for transportation, concerning the respective type of transport and ensuring the safety of the load.

15. Regulatory information

15.1 Content of volatile organic compounds /VOC/, in accordance with the Ordinance on limiting the emissions of volatile organic compounds in the use of organic solvents in certain paints, varnishes and auto reparatory products, category А, sub point c) < 40 g/l 15.2 Classification and labelling of the product in accordance with Regulation (ЕО) 1272/2008 – CLP /full text of the codes/ GHS Pictograms: No. Signal word: No. Recommendations for danger (N – codes): None. Hazard statements (H – codes): None. Precautionary statements (P – codes): P101 – If medical advice is needed, have product container or label at hand. P102 – Keep out of reach of children. P262 – Do not get in eyes, on skin, or on clothing. P305 + P351 + P313 – IF IN EYES: Rinse cautiously with water for several minutes. Get medical advice/attention. P280 – Wear protective gloves/protective clothing/eye protection/face protection. P301 + P311 – IF SWALLOWED: Call a POISON CENTER or doctor/physician. P410 – Protect from sunlight. P401 – Store at temperatures higher than +5°C.

15.3. LEGISLATION

National Legislation:

-

Law of Protection from the Harmful Impact of the Chemical Substances and Preparations

-

Environmental Protection Law

-

Health and Safety at Work Act

-

Ordinance №3 on the Minimum Requirements for Safety and Protection of Workers When Using Personal Protective Equipment at the Workplace

-

Waste Management Act

-

Ordinance №2 from 23.07.2014 for Waste Classification

-

Ordinance on the Order and Method of Classification, Labelling, and Packaging of Chemical Substances and Preparations

European Legislation:

-

Regulation (EC) 1272/2008 – CLP from 16th December 2008, concerning the classification, labelling, and packaging of substances and preparations

-

Regulation (EU) 830/2015 from 28th May 2015

16. Other Information

16.1. Indication of changes Format in accordance with Regulation (ЕО) 830/2015 from 28th May 2015 amending Regulation № 1907/2006 (REACH) of the European Parliament. 16.2. Training Advice In addition to the training programs on environment and health and safety of the workers, the companies need to be sure that their workers read, understand and apply the requirements of the MSDS. 16.3. Additional information See the application(s) of exposure scenarios for the following substances: The basic information of the exposure scenarios of the substances in the mixture are included in points 1, 2, 3, 8, 11 and 12.

16.4. Disclaimer

This safety data sheet and the data inside of it are based on industrial and commercial experience of many years and are fully complied with the current active legislation of the Republic of Bulgaria and the European Union. This safety data sheet is not intended to guarantee any specific properties and qualities of the product. The information inside of it is reliable but, on the circumstance, that the product is used in accordance with the indicated conditions and the application, specified on the package and/or in the technical literature. Responsibility of any other use of the product, including when using it in combination with another product or process is completely under the responsibility of the user. It is understood that the user is responsible for defining the appropriate precautions and for applying the legislation, concerning his own activity.

Technical Data

| Resistance to vapour permeability | µ = 410 |

| Consumption | – Dragged: 1.5 mm – 2.5 kg/m², 2.0 mm – 2.9 kg/m², 2.5 mm – 3.6 kg/m², 3.0 mm – 4.3 kg/m² – Scratched: 1.0 mm – 1.9 kg/m², 1.5 mm – 2.8 kg/m², 2.0 mm – 3.5 kg/m² |

| Reaction to fire | A2 – s1, d0 |

| Resistance to rain - under normal climatic conditions – temperature 20° C and air humidity – 50% | after 24 h. |

| Group | А+White | B | C | D | E | F |

| Price | see price list | see price list | see price list | see price list | see price list | see price list |

| Package | 25 kg | 25 kg | 25 kg | 25 kg | 25 kg | 25 kg |

Related Products

Products for therm-insulation systems

Products for therm-insulation systems

Primers and impregnators

Products for therm-insulation systems, Product series top mix

Products for therm-insulation systems, Product series top mix